So I had at one point considered holding out on buying a drill press, just biding my time until I finally get a knee mill, which will absolutely do the same job as a drill press does.

But then I stopped considering that.

In hindsight, a benchtop drill press is compact enough, and cheap enough, that I really shouldn't have worried about the extra shop space it would take up, and it's still very convenient to have a drill press around alongside a mill (whenever it is I finally get one).

So, let's get this unpacked and set up.

It's always a good sign when the styrofoam is broken, but nothing seems to be damaged or missing, so we're still off to a good start.

Hmm, I don't have a friend handy, and few if any of my foes are trustworthy. It's a good thing that I am an army of one.

Anyway, this shouldn't be too hard. The foot bone connects to the - leg bone. 🎶

Then the table goes on, complete with its sticky layer of cosmoline.

Pro tip: Boeshield T-9.

The head goes on next.

And then we check the runout on the spindle.

Actually, on second thought, let's just assume it's fine. It's probably fine.

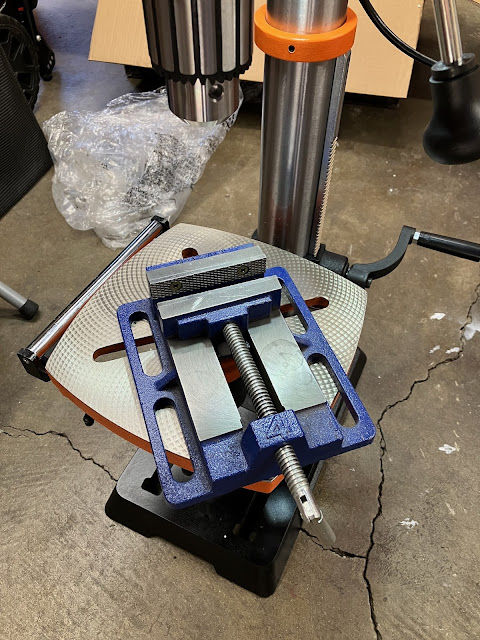

I already had the drill press vise, as it's a very useful workholding tool even without a drill press.

The t-nut clamp kit will be arriving tomorrow. It's not critical to completely bolt down the vise, but it's nice to have at least one bolt through it to keep it from helicoptering if the bit should catch.

And just to be sure, it does poke holes in things.

Granted this aluminum-havarti alloy is softer than the head of an oil pan bolt, but it's still nice to have actual evidence that the drill press can push a bit through it.

No comments:

Post a Comment