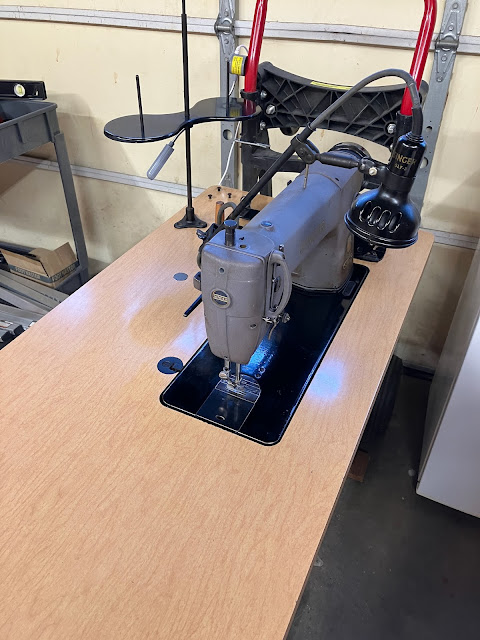

So I had mentioned in a previous post that I picked up this machine for the low, low price of free. The reason it was so dramatically discounted was because the people who owned it, having inherited it from an elderly neighbour (likely the original owner?), could not figure out how to make it sew. "It just makes loops of thread under the fabric" the Craigslist post said.

For those with a keen eye, you'll recognize immediately that there was no problem with the machine at all.

In fact, what had happened was that the machine had not been properly threaded. The needle thread was sitting on the outside of the tension discs on the face of the machine, rather than between them as they should have been. The timing was also a little bit out of adjustment, but was close enough that it should have been serviceable.

So, the first thing I did when I got the machine at least reasonably cleaned up was to rethread it properly and adjust the tensions. The bobbin tension was way too high to start with (people have a tendency to, for whatever reason, try to tighten down the tension screw on the bobbin case all the way, resulting in way too much tension on the bobbin thread), and the tension on the needle thread was equally too high to match.

I loosened off the bobbin and the needle thread, stuck in a reasonable substitute for a piece of fabric, and sewed a perfectly respectable line of stitches.

Or two lines, I guess. And technically this is after I fixed the timing.

However, something was still amiss, and it was in fact the reason that the machine had been misthreaded in the first place.

You see, on the back of the tension unit, there's a small pin that sticks out. This pin actually goes right up through the center of the unit all the way to the front side where it rests against the spring plate.

When you raise the presser foot, a small lever pushes on this pin, and that forces the spring plate away from the tension discs.

It's not super easy to demonstrate in a photo, but the tension discs are loose here because I'm pressing the unit down against the bed of the machine and the pin is being pushed up against the spring plate.

Anyway, this lets you do two things: it lets you pull the fabric out of the machine without fighting the needle thread tension, and it also lets you thread the machine more easily, as the needle thread can just slip in between the slack tension plates without having to be forced between them.

But, over time, say over the course of 67 years, this pin, lever, and spring plate can wear to the point where raising the presser foot no longer takes the spring pressure off the tension discs.

This is a very common issue, and luckily has an easy fix: spend $12 to buy a whole new tension unit.

Of course this means I'll now need to readjust the take-up spring tension and position, since it's integrated with this tension unit, but it's a small price to pay for getting the presser foot tension release functionality back.