So it's about time to wrap up this bike build.

And by "wrap up" I mean wrap the bars in bar tape. First though, let's stick the bar gels on the drops, to smooth out those rough descents.

The bar tape I chose for this build is rather vibrant, and at first glance you might think that it would look jarring next to the almost pastel purple of the frame, but there is a method to my madness.

If you want to tie a color scheme for a bike together, you have to use the color in at least two places. In this case, the rainbow bar tape matches the cassette and chain, and serves to unify the front and back of the bike with a continuity of accent colors. The whole bike then becomes a harmony of purple, black and rainbow, the same notes over and over, and it all comes together.

But for that to happen we first need to get the tape onto the bars, and the start is always the trickiest part.

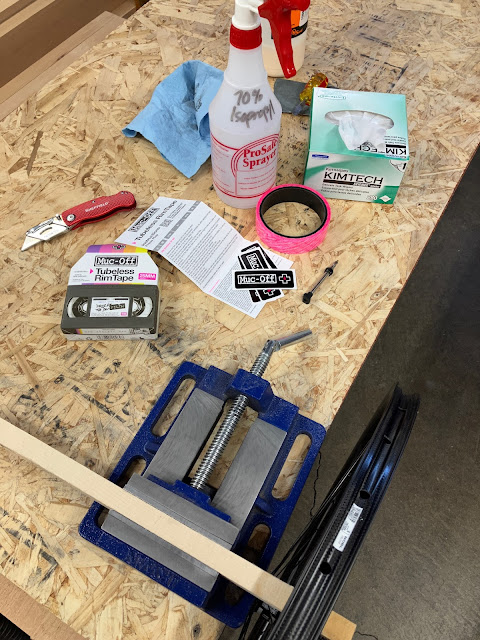

So I cheated, by applying a wrap of double-stick tape.

If you've never wrapped a handlebar before you might wonder what's so tricky about the first few wraps, and the answer is that most bar tapes only have a narrow strip of adhesive down the very center of the tape, and that adhesive ends up spiraling off the end of the bars on the first wrap, leaving nothing to grip the bars at all. This Shimano/PRO tape goes one step further and replaces the adhesive with a strip of some silicone-like material with only the slightest suggestion of tackiness, so I'm really going hard mode here. Anyway, the double-sided tape here ensures that the first wrap or two doesn't move when I'm applying the bar tape, nor when I fold the loose end into the bar and install the bar plug.

Now I was only born with two hands, so it's sort of impossible to take good in-progress photos of the bar tape wrapping, so you'll have to excuse me for fast forwarding past that part and just showing the result of wrapping the first side.

The end is just hanging loose right now with a bit of electrical tape to hold it while I do the other side, so that I can come back to make any needed adjustments to make them match.

Speaking of the other side...

It went just as smoothly as the first.

I should mention here that there's essentially four different ways to wrap handlebar tape, all of which produce basically the same result. You have two choices for the spiral direction, wrapping towards the bike frame or away from it as you come over the top of the bars, and two choices for which end to start from, either starting at the bar ends and wrapping towards the stem or starting at the stem and wrapping towards the bar ends. I chose to wrap starting from the bar ends and spiraling away from the bike frame, but that's just a personal choice, and you should feel free to use any of the other three incorrect methods if you so please.

Also, in case you're curious, the black rod in the picture is a flop stop which, as the name suggests, stops the handlebars from flopping around when doing work like this. It's well worth the modest investment.

Anyway, as you can see, the wrapping went great and I will fully admit to using a cheater strip to cover the gap that naturally forms when crossing over the levers.

Some people prefer to omit this strip, and simply leave this part of the bars bare. If you see someone riding that, the best thing to do is to call the police as this person is almost certainly a psychopath.

The real measure of a wrapping job, though, is how even it turns out, and I think I'd have a hard time getting it any more even than this.

Also I have a garmin mount here. I didn't take a picture of it earlier, but here it is.

While we're putting the finishing touches in place, let's take care of the bottle cages and accessories.

We've got a pair of Specialized Rib Cage III in a lovely gloss black carbon fiber, a Specialized Zee Cage in matte black plastic holding a Topeak tool pouch, and a Lezyne mini pump / inadvertent valve core extractor to round things out.

I'm not 100% sure if I'm going to keep this tool pouch arrangement long term vs using the Dakine Hot Laps Gripper (what a name) that I use on most of my other bikes, but the cage mount happened to be here and I figured I'd give it a shot. Mostly I'm concerned that it might foul with the front fender that I'm planning to mount for winter riding. We'll see how it goes I guess.

But before it goes, it needs to stop. Thankfully the new lockrings came in.

It's pretty easy to see how they'd give more clearance to the frame, and they just simply install with a cassette tool rather than a bottom bracket tool (both of which I own).

However, that doesn't mean that things necessarily went to plan.

You see, I bought two of these, even though technically only one lockring needed replacement. My plan was initially to also replace the front lockring on Purple Haze, my Tarmac, as while it wasn't rubbing, it was awfully tight between the lockring and the fork.

But I quickly discovered a flaw in that plan. The axle cap on the DT 240 hubs on that wheelset, for whatever reason, has a slight taper to it, and the cassette tool jams against it before it's able to screw the lockring all the way tight. That's not ideal, not even a little bit.

Thankfully it's also not a huge worry for me, since the old lockring was working fine. I reinstalled it and just left it be, and turned my attention back to the new bike.

Thankfully the axle cap on the DT 350 hubs I opted for didn't have the same taper issue, and I was able to install the lockring with no trouble whatsoever. However, I decided that it would be nice if the lockrings matched between the front and rear, and since I now had a spare matching lock ring, I went ahead and tried to install it...

Only to discover that the axle cap is too long on the rear hub, and the cassette tool bottoms out on it before it gets anywhere close to screwing the lockring in place.

So I guess that settles it, the lockrings are going to be mismatched.

At least the front wheel spins now.

So with all the parts in place, there's only one thing left to do: weigh it! According to my not-at-all-suspect discount amazon fish scale, this beast is being pulled towards the earth with a sum total of 19 freedom pounds of force. This compares with 16 lbs for Purple Haze, my Tarmac, and 21 lbs for Dirty Dozen, my CAAD12. Very respectable.

Ok, now for the real one thing left to do: ride it. For a bike like this, the only natural thing to do is to ramble down a dusty country road, past rustic, untamed wilderness 100 miles from nowhere.

Some say it knows two facts about ducks, and that both of them are wrong. But all I know is it's called The Stig.

Also it's probably worth mentioning that this dusty country road through rustic, untamed wilderness might actually be in the middle of San Jose, which at least qualifies as being something like 100 miles away from the nearest place that might be considered "nowhere".

But there's nice views at least.

I'll take it on a longer ride later.