The first batch of parts have arrived, and so we can do a little bit more work freshening up the sewing machine. First, and perhaps most importantly is sewing machine oil. This bottle should last me a lifetime.

Or several, if I'm talented.

I got some cork to freshen up the treadle, but decided that I'm going to use this roll for refreshing a tool box, as it's a bit thinner than the original cork and I later discovered that you can buy a pre-cut cork pad that fits exactly in this spot.

But that toolbox is a project for another day.

One thing that industrial machines often lack is a built-in light, and so since the arm of the machine casts a pretty big shadow, adding a light is an important upgrade.

This gooseneck light is pretty nice, and sticks very firmly to the chassis of the machine by way of a magnetic base.

It's a pretty nice light, though I also purchased a pre-cut LED strip light that I might mount to the underside of the arm.

I could then use the magnetic lights on my domestic machines, which do have built-in lights, but the more the merrier.

One important maintenance item for an industrial machine is the drive belt.

The belt that came on this machine isn't half bad, but it was feeling a little bit dry and a new belt is only $7.

So on it goes.

Next up are needles. Picking the right needle for the job can make all the difference in the world.

The machine came equipped with a 120/19 size needle, which is good for medium weight threads in the range of Tex 70 to Tex 90.

And the thread that was left over in the machine is...

Tex 27, a pretty standard lightweight domestic serger cone thread. That's quite a small thread for this size needle. Generally you'd use an 80/12 or 90/14 for this weight thread. Here's a 90/14 needle next to the 120/19 that was in the machine, for comparison.

With the 90/14 needle installed, the stitch quality in a folded paper towel looks pretty good.

I just happened to have a folded paper towel on hand.

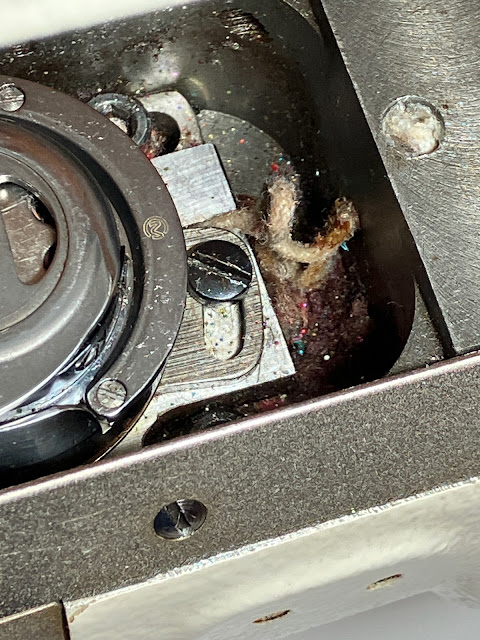

Of course, the reason I had paper towels on hand was that the machine desperately needed cleaning. For example, the bobbin compartment was full of lint and glitter.

I got quite a bit of gunk pulled out, though certainly not all of it. One can never truly eliminate all glitter.

But this gunk was nothing compared to the amount of lint and glitter up in the arm.

It's unfortunately a bit difficult to see in this picture, but there's a lot of crap caked on here with gummed up oil.

This is only about half of the grime I pulled out.

Admittedly from the outside it doesn't look much different, but it's what's inside that counts.

And that's about enough work for today.

No comments:

Post a Comment