So my bandsaw is equipped from the factory with a dust collection port. I do not have a dust collector, which is a roughly fridge-sized box that takes 240v of electricity and turns it into noise with the side effect of sucking dust and chips out of whatever's attached to its 4 inch pipes Absent this dust collection, the bandsaw has a tendency to produce a cloud of fine wood dust when sawing that then covers every surface in the shop, much to my annoyance.

But while I do not have a dust collector, I do have a shop vac. While this also turns electricity into noise, it does so at a much slower rate, only sucking in dust via a 1.75 inch inlet rather than the 4 inch inlet more characteristic of a proper dust collector. However, with that deficiency in mind, I decided to try to see if it would be useful to adapt the dust collection port on the bandsaw to the hose on the shop vac.

Enter: a plywood monstrosity.

This monstrosity was born into this world with a few deficiencies.

- The plywood it's constructed out of is kind of half rotted and water damaged and falling apart.

- The plywood it's constructed out of was never actually good in the first place.

- The 4 inch hole is tapered. This is because I cut it out with a jigsaw, and when you cut out curves with a jigsaw the blade deflects towards the outside of the curve while you're cutting.

- It's also just kinda ugly.

However, all those issues aside, the one thing it does do is actually work. I hooked up the shop vac and cut a few test boards and I was mightily impressed to find that pretty much all the dust got sucked up by the vacuum, despite its anemic relative performance when compared with a dust collector. I had initially hoped that it would at least collect the fine dust that tended to spread through the air a lot, but it even collected the heavier dust that usually settled around the base of the machine. Sweet.

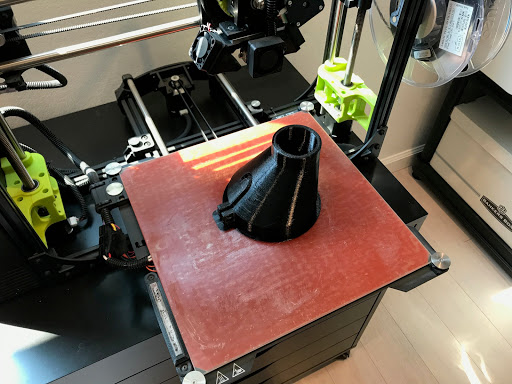

That said, it still had issues, so to address those I did what I probably should have done in the first place and 3d printed an adapter out of black PETG.

The J-shaped cutout is to allow the bolt-and-threaded-insert to clamp down onto the outside of the dust collector port without causing stress risers in the plastic that might shatter it later. It also probably lets in a lot of air but if that becomes a problem I'll just slap some duct tape on it.

Long story short, I'm quite pleased with how this turned out and I expect that this'll make my use of this tool a lot more pleasant.