For a while now, one of my tea towels has had an issue.

Specifically, it's had a small hole in the relatively coarse waffle woven fabric.

Now this is certainly not the first time I've had to deal with fixing holes in fabric. For example, the handle on one of my shopping bags got caught in the trunk lid catch of a rental car once.

I used a back-and-forth technique on this repair, using my Brother CS6000i, and it went rather slowly due to it being a computerized machine (computerized machines tend to be very slow when sewing backwards).

More recently, as in earlier this week, I went through and darned all the holes in my wash cloths using my Brother Nouvelle 1500

The wash cloths in particular turned out very good, with the repairs only barely visible.

Since the Nouvelle 1500 is a mechanical machine, it can sew in full speed going forwards or backwards, and can transition between the two basically instantly.

That meant I could just put my foot to the floor and toggle the reverse lever with my right hand while my left hand guided the fabric such that it would slowly walk from right to left as the sewing machine fed it back and forth.

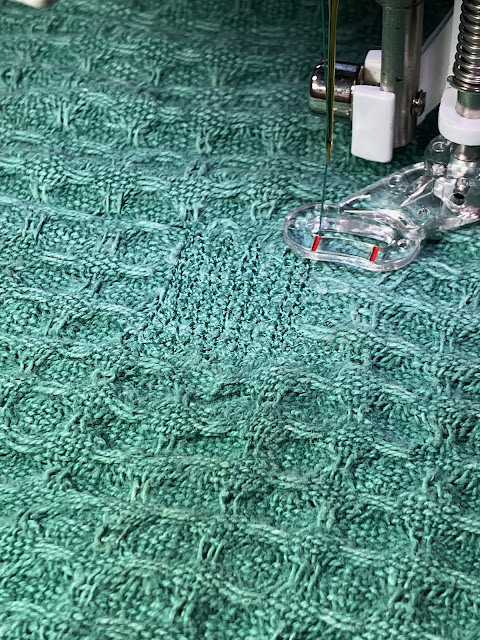

For the tea towel, however, I decided that I wanted to try out free-motion darning, and so it was back to the CS6000i, since that's the only machine I have a free motion foot for.

On a smaller machine like this it also helps to have an extension table, so that you have a bit more room to plant both hands on the fabric while you're moving it back and forth.

And don't forget to drop the feed dogs.

But before we get to the darning, we need some matching thread, and in terms of sewing thread I don't seem to have any good greens for this particular shade of faded tea towel.

The leafy green would have been a bit too bright and the mossy green would have been a bit too brown. The neon green would have been obviously a bit much.

Of course, I do also have machine embroidery thread.

The colour match is almost spot on, which is great. The only downside is that embroidery thread tends to be a lot glossier than sewing thread, but I think I'll be able to get away with it.

So we'll wind up a bobbin (which feels a bit weird to do with embroidery thread) and then get to sewing.

Curiously, free motion darning is one of those techniques where it's actually a lot easier to go fast than it is to go slow. The fabric only moves when the hopping foot is up (the needle bar screw lifts up against a bar on the foot at the top of the needle stroke), and so having that motion happen more frequently makes the motion much smoother.

So the trick is to drop the hammer and just go for it.

The hole closed up nicely here, but I've only done the darning in one direction (vertically in the photo). I turned the work 90 degrees and did another pass to ensure that nothing would be coming apart again.

The waffle weave did obviously flatten out a lot in the darned section, but it shows up a lot less in person than it does on camera.

And with the hole patched up, there's nothing left to do but put it back in service.

Not that I would ever hang towels from the oven door handle. No, not me, no sir.

No comments:

Post a Comment