Most standard lockstitch sewing machines are capable of using a specialized presser foot most commonly known as a "walking foot", although this is a little bit of a misnomer. It's a little more accurately described as an "even feed" foot, and I'll explain why that is in a moment.

My new-to-me Brother Nouvelle 1500s can take one of these feet, which is convenient as it's a quilting-focused machine and an even feed foot is very useful when trying to feed a quilt sandwich (composed of the quilt top, the batting, and the backing fabric) evenly through the machine, without getting puckers and curls caused by the different layers shifting or stretching relative to each other.

However, the original even feed foot was not included with the machine, so I took a gamble and tried buying a high-shank even feed foot off of Amazon.

This did not quite go as planned. Above we can see the Brother's regular high-shank presser foot on the right, a standard snap-on zig-zag foot to the left, and the high shank even feed foot in the middle.

What's wrong with this picture? Well, this particular even feed foot is designed for a high shank zig-zag sewing machine, which my Brother definitely is not.

Now technically I can install this foot, and I can sew through it without the needle striking the foot. However, all is not as it should be.

You see, the way this even feed foot is designed, the middle portion lifts up when the needle is at the top of its motion, and the two outer runners slide back and forth with the fabric to achieve the even feeding motion that the foot is named for.

However, this doesn't work at all if the outer runners don't actually line up with the feed dogs.

It's a little easier to see if I compare how the even feed foot from my low shank zig-zag machine lines up with the feed dogs on my straight stitch machine.

On this foot, the metal portion holds down the fabric when the needle is making a stitch, and then the white plastic pieces are pushed down against the feed dogs when the fabric is being moved through the machine. If they don't line up with the feed dogs, the fabric doesn't move.

Luckily, I was able to find the correct even feed foot for this machine.

This one is designed specifically for high shank straight stitch machines, not zig zag machines, which means the foot is much narrower in comparison with the zig zag even feed foot, and the mechanism lines up with the feed dogs properly.

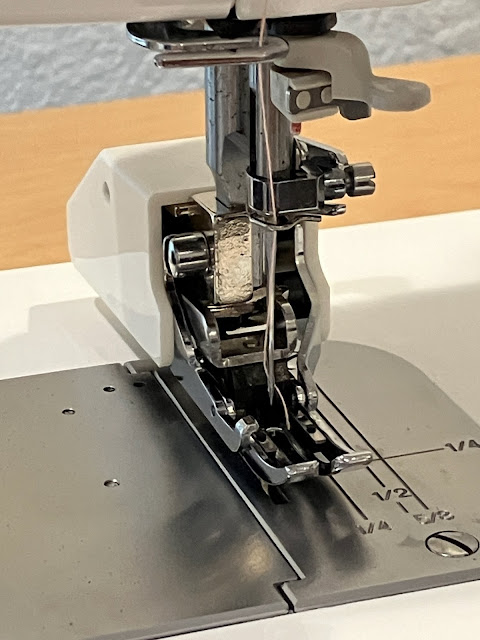

We can see here how the black plastic runners line up perfectly with the feed dogs.

And so the fabric layers will be correctly pinched when the feed dogs are advancing.

And this is the secret to the even feed foot: the runners in the foot slide back and forth in unison. The fabric that's already been sewn, behind the needle, will always move as one thanks to being stitched together, but with a regular fixed presser foot the fabric in front of the needle can be dragged forwards by the friction against the underside of the foot. With the even feed foot, the runners get pulled backwards in the rear by the stitched fabric, and this then is translated into the runners pulling the fabric in front through the machine at the same rate, preventing the stretching, pulling and puckering issues.

A walking foot is notably different here. On a proper walking foot machine, the foot's feeding motion is directly actuated by the sewing machine, rather than simply passively sliding back and forth as the fabric is moved by the feed dogs in the needle plate. Walking feet also generally have a much higher stepping action, which makes them able to walk up over much bulkier seams, like those you might run into when sewing leather and thick vinyl.

But anyways, after only a little bit of a struggle with ordering the wrong part (thank goodness for Amazon returns), I have the correct even feed foot for my straight stitch machine.

No comments:

Post a Comment