My Juki LS-321 came equipped with a clutch motor. It's pretty smooth, plenty powerful, and not incredibly noisy. That said, it doesn't really have the control that a servo motor has, and I'm planning to use this machine for some pretty small and intricate projects. Given the choice, a servo motor would be more appropriate for the task.

But since I had a clutch motor already, I didn't really fancy the idea of swapping to a servo motor, since then I'd have a clutch motor just sitting around taking up space, or I'd have to try to unload it on Craigslist, or whatever. Not a really appealing option.

Fast forward a little bit and a Consew 18 falls in my lap as a head-only purchase, meaning it'll need a motor of its own. So the opportunity presented itself: move the clutch motor from the Juki to the Consew and buy a servo motor for the Juki.

So naturally that's exactly what I did.

These instructions probably make more sense in Chinese, but luckily things aren't too difficult to figure out.

I will have to learn how to unhold a button, though.

Anyway, things are pretty self-explanatory so it's not a big deal.

Before we stick the new motor on, we first need to get the old clutch motor out of the way.

One of the advantages of using a servo motor is that, for the same power (about 550w), the servo motor is much smaller than a clutch motor.

But I perhaps didn't really appreciate how dramatic of a difference it would be.

I'm not sure how much of a noticeable impact it makes once it's installed though, since it just hangs out under the table. And speaking of installing, let's get the motor bracket and motor bolted in place.

And hook up the actuator rod from the pedal to the speed controller.

And mount the actual servo driver.

This servo motor goes up to 5000rpm, which is another advantage I didn't mention earlier. The Juki LS-321 is rated to go up to 2400spm, and with the previous setup it had a small pulley on the 1750rpm clutch motor which resulted in a top speed of around 1050spm. The servo motor on the other hand has a pulley that's only about 10% smaller than the machine's pulley, so the 2600rpm I've configured here translates into 2356spm up at the machine.

And I can get there without sacrificing the slow speed performance, which is really nice.

Speaking of slow speeds, one of the other advantages of a servo motor, or at least a brushless servo motor like this one, is that you can equip it with a needle positioner.

This is basically a simple encoder that you clamp onto the end of the main shaft of the sewing machine, so that the servo driver knows exactly when to stop to put the machine into either a needle-up or needle-down position, rather than just letting the machine stop wherever it happens to stop.

And if you do happen to choose the needle-down position as your default, a simple heel press on the pedal will make the controller spin the head to the needle-up position so you can remove the work.

Of course, if you only attached the encoder to the main shaft, it would likely spin wildly when the machine is running and not report anything sensible to the controller. To fix that, they provide this peculiar little bracket that you can use to keep it steady.

I think it's usually intended to fasten onto a belt cover or something, but I don't really feel like ever installing a belt cover, so I just positioned it so that the threaded rod is nicely wedged inside of this convenient hole in the main casting. It does the job just fine.

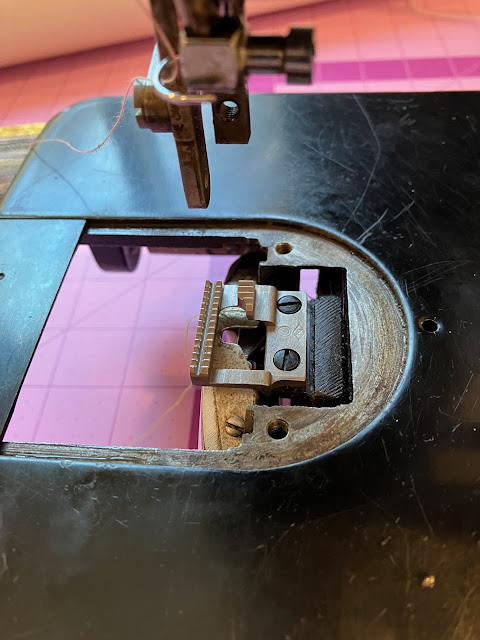

On the subject of positioning things: since I put a new motor in and changed the belt geometry, the bobbin winder will have to be readjusted, which is a pretty simple task to do. Just loosen the screws and position it so that the belt doesn't touch the drive wheel when it's disengaged.

And does press up against the wheel when it's engaged.

Simple as that.

Last but not least, I suppose I should probably figure out some place to put the motor's pulley cover. I guess this is as good a place as any to stick it.

And with that the job is done. The machine sews beautifully with its new motor; it's easily controllable down at low speeds, and putting the pedal down makes it spin up over twice as fast as it used to. A very worthwhile upgrade that I'm glad I finally found the opportunity to perform.