Or at least it would appear that way according to what I just ordered.

This is the Hakko FR-301, obviously, and there's really no reason I bought the Japanese version; they do make a basically identical American version with english packaging and documentation and a 3-prong plug. And it's also $100 more expensive for some reason.

I suppose I should explain what this is: it's a desoldering gun. To desolder a component, you generally need to heat up the solder past its melting point, then somehow physically remove the liquid solder from the joint. You can wick it away with solder wick, or suck it away with a separate solder sucker, but this tool combines both the solder sucking and the heating in one single tool.

It's also, somewhat inconveniently, designed to run on 100VAC, since it's the Japanese version. So we're going to need to do a little bit of tweaking.

The back cover and solder jar come off quite easily without tools, and then there's 4 screws on the case and 2 on the nozzle that need to come out.

Is it scandalous to see it this naked? Anyway, 2 screws on the PCB and 2 more on the power cord strain relief need to be removed to free up the main PCB.

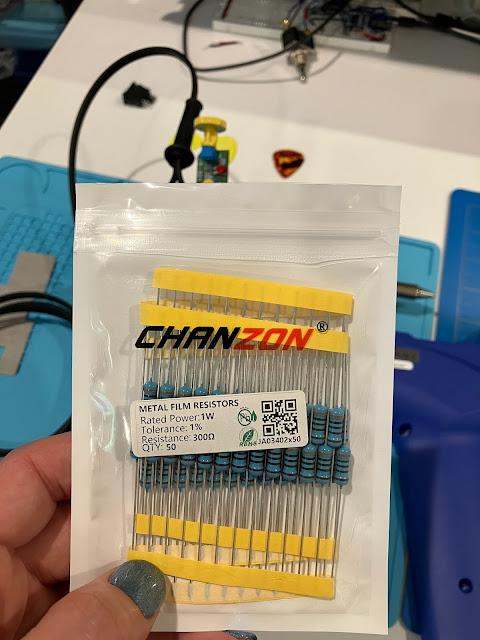

What we're looking for is the 10Ω resistor that runs in line with the vacuum pump motor, which needs to be swapped out with a pair of 300Ω resistors to get it running the correct speed at 120v.

And yes, I now have 48 spare 300Ω 1W resistors that I'm sure I will find a use for... eventually.

Anyway, to remove the 10Ω resistor we can just use the desoldering gun to... oh, wait.

Right, we gotta do this old school.

This is, quite frankly, a giant pain in the ass thanks to the use of lead-free solder. But I managed.

Thankfully soldering in the two new resistors is pretty easy. Remember to space them off the board so that they don't cook the PCB when they warm up.

And don't forget to clean off the flux when you're done.

Curiously the trimmed leads from these new resistors are magnetic, apparently having been made from tinned iron wire, rather than something like, I dunno, copper?

Given that these resistors are THAT cheap, it's probably not a bad idea to check to see if they're even in spec.

Ok, that's actually not too bad. And since I have a 4-wire meter, I can also check to see how much resistance is coming from the iron component leads themselves.

You really need a 4-wire setup for this as otherwise the resistance from the test leads and the contact resistance from where you connect to the component you're testing will overwhelm the low resistance you're trying to measure.

2mΩ ain't half bad, I guess the iron wire does the job if it's thick enough.

Anyway, assembly is the reverse of disassembly.

And we're ready to suck some solder!

No comments:

Post a Comment