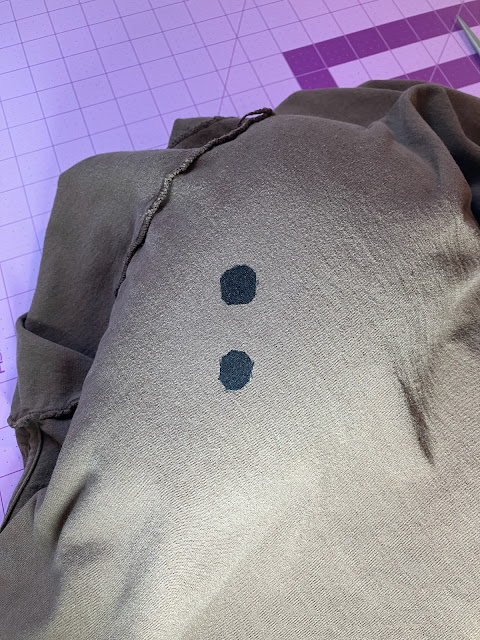

On the gurney today rolling in for treatment is one of my t-shirts, which happened to grow a few unfortunate holes on the back of one of the shoulders.

Since t-shirts are a knit fabric, you really don't want to leave holes like this alone, as they'll have a tendency to grow over time. So let's dive in.

The first step is to apply a bit of ultra-light knit interfacing to the back. This mostly comes in either black or white, and since we're dealing with a dark colour the black will blend in a bit better if it happens to show through somewhere.

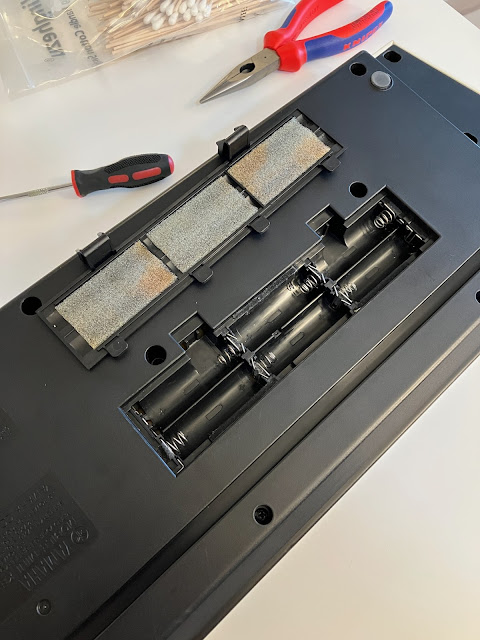

The good news is that I have a roll in my stash. The bad news is that it's definitely not knit.

Yeah, that's definitely woven. Sigh. Well, whatever. T-shirts don't need to stretch all that much, and I can just apply it on the bias and it'll be fine.

So, on it goes.

And even without doing anything else, we're already looking quite a bit better. The glue on the interfacing is holding down the loose threads nicely, though the fact that we also just pressed it with a hot iron is certainly contributing to the improvement too.

And on the backside, things look well adhered.

But a little light heat-set glue and some pressing isn't going to last more than a few trips through the wash, so we need to get things secured a bit more permanently. Last time I used machine darning to close up the holes, but that leaves quite a bit of thread showing on both the front and back, and I want something a bit more hidden this time. So, we're going old-school.

We need a very fine needle for this work to prevent punching huge holes through the fabric, and a #12 is about as fine as you can readily get these days.

I'm not sure the black oxide coating is really all that much more special than a chrome or titanium nitride coating, but whatever, they'll do the job.

So in we go with a basic running stitch. Since t-shirt fabric is knit stockinette, it tends to stretch from side to side, but not up and down. So we'll do the stitching on the bias (much like how we applied the interfacing) and even go a little further by angling both directions of stitching more vertically than a plain 45 degrees.

The goal here is to keep most of the thread on the back side here, catching only enough of the front of the fabric to keep the stitches secure. This will minimize the visibility of the stitches on the right side.

Once we've stitched back and forth in one direction, we come back across at the opposite angle.

We also want to make sure that we're not pulling the thread tight. It should be just pulled through so that there's no loose loops, but not making any pulls or puckers in the fabric. Also, since I'm using a somewhat slippery polyester machine embroidery thread here, tying off both ends is vital for keeping everything in place.

We don't need to completely bury the patch in stitches, just get it sewn down enough so that it fully reinforces the hole and can't come up around the edges.

From the top side, we can see that we were largely successful with keeping the stitches from showing through.

However, with a raking light it's still obvious that there's some unevenness here.

This is unavoidable, but we'll be rectifying it shortly. But first, we need to sew down the second patch.

Speaking of sewing, and especially since we're using a very fine needle, now is a good time to cover the proper use of a thimble. The uninitiated might assume that the thimble is intended for the off-hand, to armour one's fingertips and protect them from the jabs of the pointy end of the needle. However, this is not the case.

Rather, it is for wearing on the sewing hand, and is used to push against the butt of the needle when you're forcing it through the fabric.

A needle that's fully woven through the fabric like this can take a fair bit of force to push through, and the thimble prevents the butt of the needle from pushing back through your finger while you're applying that force.

Anyway, second verse was the same as the first, and both patches are now secured.

And on the front side we're once again greeted by stitches we can't see, but puckers we can.

At least in this harsh, raking light.

But the solution is as obvious as it is straightforward: pressing.

The heat of the iron on the "cotton" setting actually softens the polyester thread, causing it to conform to the shape of the stitches. This both allows the fabric to flatten back out, as well as kinks the thread so that it's much less likely to shift or pull out as the fabric moves around during wear and washing.

And now, particularly in much less harsh light, you'd be hard pressed to see where the darning was even done, unless someone pointed it out to you.

Ok here, I'll point it out to you.

The slight light spot you can see is only really visible in the photos, and is just due to the pressing having flattened some of the natural fuzziness of the t-shirt fabric. It's not apparent in person, and will vanish completely after the next washing.

So, chalk up yet another successful repair.